Trolley Scan(Pty) Ltd

Trolley Scan(Pty) Ltd

What can we do with half a watt? To have a transponder system which is going to be low cost for manufacture, and give ranges of 4 to 6 meters, the chances are that it will be passive and operate somewhere in the UHF frequency band, and more specifically in the 400MHz to 930MHz band. Passive indicates that the tag does not have a battery and receives its energy from an energising field from the reader. The strength of that field and the RF sensitivity of the transponder determines the range at which transponders will receive sufficient power to operate. When very low cost E-field tags were first developed in South Africa in 1991, energising field strengths of about 100 watts (ERP) were needed. Although this sounds a large number it is achieved by using a cell phone car booster and a simple antenna and is very safe. US regulations required this to be reduced to 30 watts to fit their spectrum planning (a 4 watt amplifier and a simple antenna). Europe has had a number of different regulations and as part of unification has allocated a band that can now be used for RFID but has set the power threshold for the reader at ONLY 0.5 WATTS (ERP) but information is that this level is soon to be increased. Conventional passive tags would be lucky to achieve operating distances of 25cms on such a low power. EcoTag was borne in South Africa in April

1999 as the result of research by Trolley Scan, the inventors and

developers of Trolleyponder®.

Hoping to increase the operating distance of their transponder system by

a few centimeters, their research has led to measured improvements in the

energy conversion of transponders from the RF energy received at the antenna

to the operating circuit in excess of 200 times . This means that a passive

transponder operating in the UHF band can now be read over a zone 5.4 meters

wide if needed, and all on 0.5 watts ERP!.

Commercial

|

| The above chart compares average cost and operating range of the RFID technologies currently available. Trolleyponder® and EcoTag® technologies are UHF operating typically in the 860-930MHz band. |

Test results showing

the measured bandwidth of an EcoTag version

covering both the EU and the US

RFID frequency bands.

The above are results on a particular model of EcoTag. In a similar

manner EcoTags

can be built for other operating frequencies.

| History of power reduction development

in the 900 Mhz band

Mike Marsh has been involved in the development of Transponder systems in the 900 MHz band since inventing the first low cost multiple transponder protocols in 1990. Passive transponders extract their operating power from the energising field radiated from the reader. During the past twelve years, technological and design developments have reduced the energising power requirements needed for transponders from Effective Radiated Powers (Antenna gain times transmitter power) of 160 watts in 1990 to the EcoTag levels of 0.5 watts. In December 2003, Trolley Scan launched its EcochiptagTM version, where the EcoTag properies are applied to a simple small antenna giving good efficiency, small size and simple manufacturing methods.The sensitivity of the EcochipTag version is as low as 250 microwatts. The following graph shows the energising requirements needed in the different periods in order to obtain operating distances of 4 to 6 meters. |

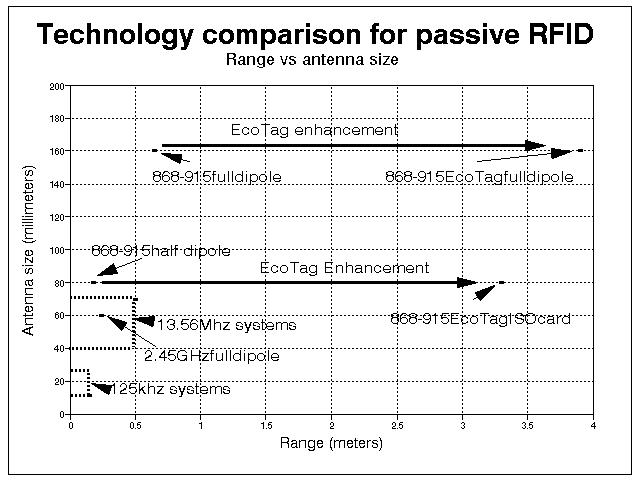

A comparison of passive RFID systems

Magnetic coupled technologyies - 125kHz and 13.56 MHz showing typical ranges

achieved with standard sized readers

Electric coupled technologies - All other systems shown based on a 4 watt

ERP energising field and 2.5 volt logic

Trolleyponder®,EcoTag®,TinTag® and EcochipTag are the trademarks of Trolley Scan (Pty) Ltd